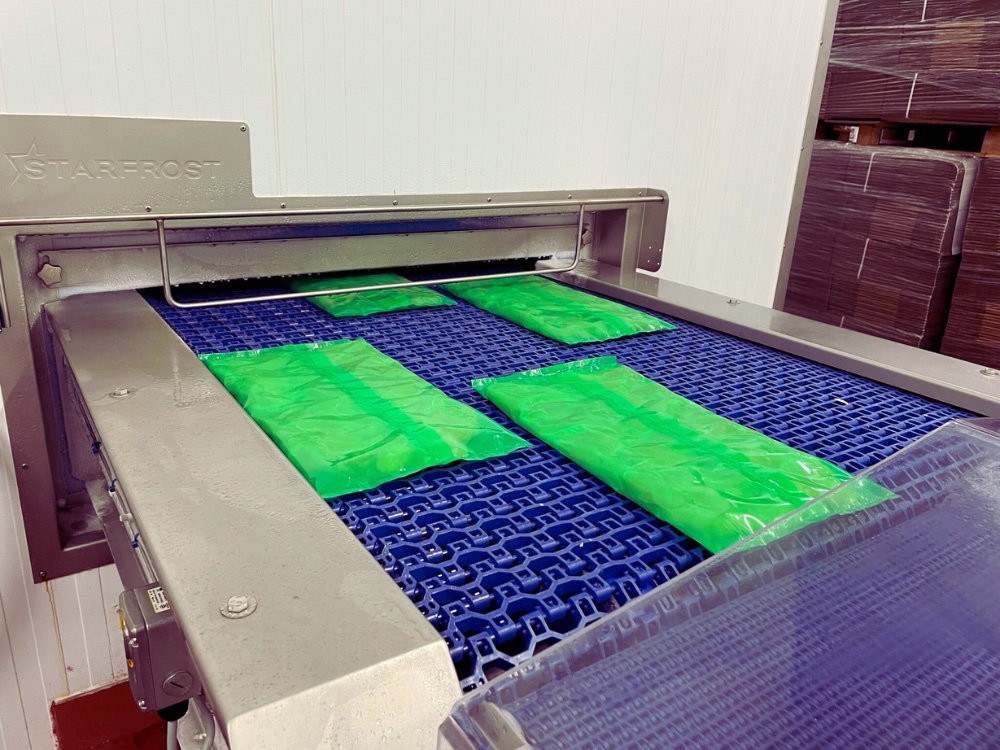

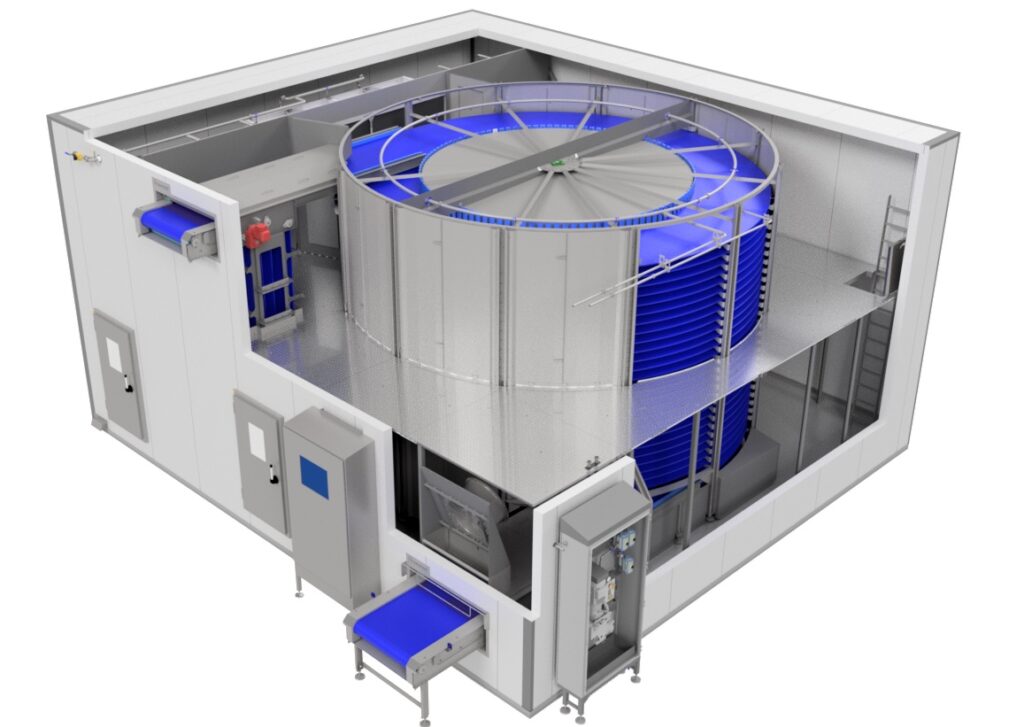

Wigan, UK: Newburgh Foods has increased its poultry block freezing production capacity by 60% with an automated Starfrost Helix spiral freezer.

The company, which supplies supermarkets and restaurants in England, had an existing contract with a fast food chain that recently increased its capacity requirements. This led Newburgh Foods to review its freezing process capabilities and seek a solution that would fulfil the substantial increase for its customer.

Newburgh Foods awarded the contract to Starfrost which supplied and custom-built a Helix spiral freezer designed to fit within the existing production layout at Newburgh Food’s Warrington factory.

Using natural refrigerant CO2, Starfrost’s equipment freezes up to 20 tonnes per day and has enabled Newburgh Foods to significantly increase its production capacity while delivering the additional benefit of increased efficiency for the firm by reducing freezing times to less than 85 minutes. This is a substantial improvement from the previously used blast freezing method, which took between 12 to 15 hours, Starfrost says.

Phil Trew, operations manager, Newburgh Foods said: “We chose mechanical freezing over a nitrogen cryogenic alternative because it better suited our criteria and, of course, due to the soaring, unstable cost of gas. We needed to produce more product in less time if we were going to meet our new contract target and Starfrost worked with us to provide a freezing system that would perfectly suit our needs and the needs of our customer while being a cost effective solution.”

“The spiral freezer has allowed us to significantly increase production capacity by 60% and substantially reduce freezing time. The quality of the engineered equipment and specification provided by Starfrost has impressed the team at Newburgh Foods.”