London, UK: The removal of the rebate on non-road going diesel fuel, red diesel, has prompted a number of companies to market engine power-take-off driven alternators to power truck and trailer fridges using the standby electric socket. But how safe is this?

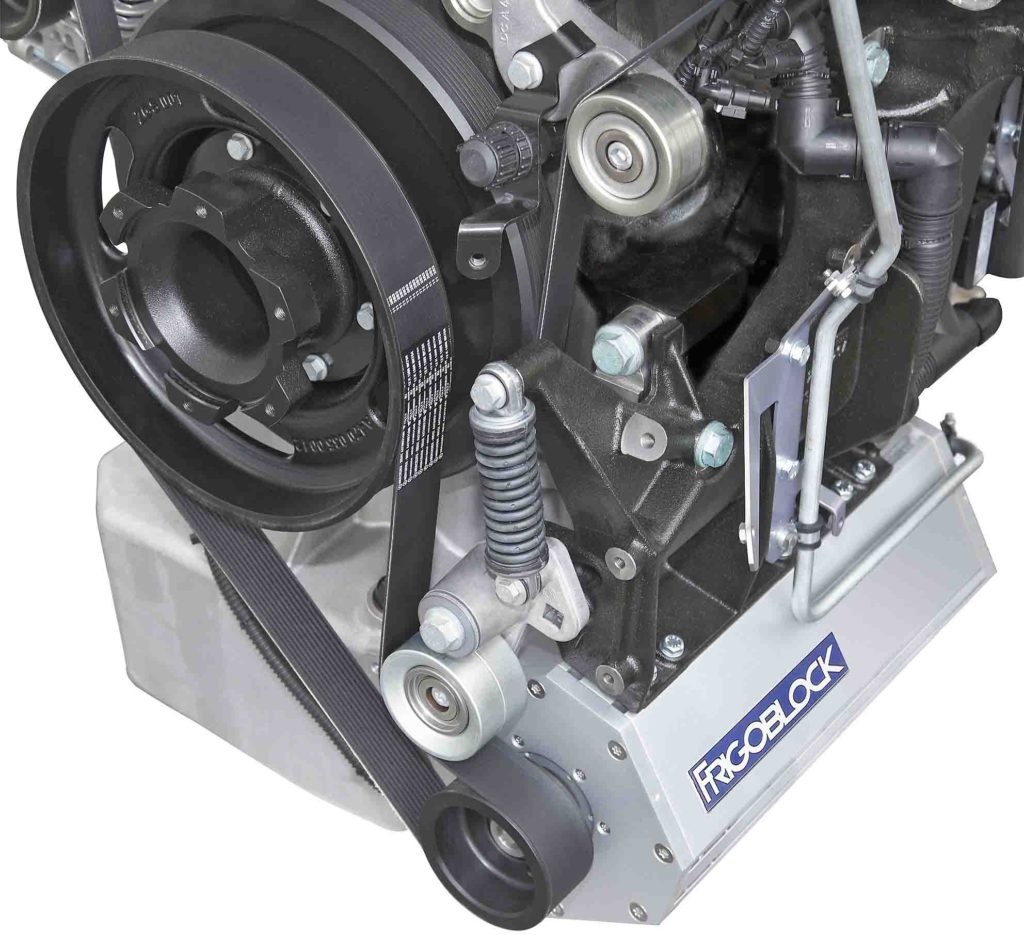

Cold Chain News asked Dale Cornes, key account manager, Frigoblock, for advice. Frigoblock has been making engine-driven alternator powered refrigeration systems for many years. Some truck makers will even fit the Frigoblock alternator on new trucks as original equipment.

There are several companies offering PTO-driven alternators that plug into the fridge standby socket to offer diesel-free cooling but Cornes cautions operators going down the DIY route of using an alternator from one supplier to power another manufacturer’s fridge.

“As a manufacturer we cannot vouch for the quality of the electrical components used by other vendors, so cannot be sure of optimum operation of the TRU and what effect the source of the drive will have on our product lines,” she says. “If the effect is dramatic it may cause additional costs to the operator (and potentially void the warranty of the TRU.

As 400 volts is transferred from the truck engine to the TRU whilst the vehicle is in motion, it would be advisable for operators to carefully check that the specification of electrical plugs, sockets and high voltage cabling conforms to all applicable safety regulations. This is critically important when transferring the current from the prime mover to trailer or drawbar through the connections when on the road. This compliance assures operators that the connections remain latched, sealed and safe to prevent water ingress.”

“All Frigoblock Envirodrive connections, plugs and sockets comply with all the European standards for electrical safety for static and in particular mobile operation.” she says. Similarly on static operation at customers’ depots care must be taken to ensure compliance. The type of electrical deployment of cables and sockets in an operation will be down to the operator’s preference and consideration given to mitigating damage.

“Plugs and sockets are always to be kept dry and serviceable to enable good conduction of electricity. Storage of the cable is also a consideration, whether using cable boxes on the point or reels to run the cable to the TRU’s or fitting cable boxes on the trailer / rigid hardwired to the TRU to run to the plug-in point.

“Each will require thought by the individual operator and ensure correct use by their staff. As there is a physical connection between the electrical point and the vehicle, sensors can be applied to the vehicle to mitigate damage from driving away with the TRU still plugged into the grid,” she says.

“There are some key differences between PTO drives and integral installations such as the SLXi Hybrid and other TK hybrids using the Frigoblock alternator. “Efficiency is our motivation, therefore we spend a lot of research and development with all the major chassis OEM to offer sound solutions through the simplicity of alternator driven from the clean and compliant E6 engine directly to the TRU.

“This simple architecture turns mechanical energy directly into electrical energy, whereas other drive systems convert the energy into hydraulic energy first then back into electrical energy. This creates a situation where the prime mover is using 30% more energy and therefore extra fuel use by the tractor and/or rigid.

“The alternator and Inverter aka Frigoblock Envirodrive, deploys a soft start to minimise mechanical stress on the E6 engine. The energy is then down streamed from the alternator to the Inverter where the alternating current is converted into direct current to optimally deliver the 400V electrical supply to the TRU. Through intelligent software on the Inverter it enables an advantage to run the SLXi at 60Hz and delivers even greater performance. The Frigoblock Envirodrive (alternator and Inverter) with 93% efficiency has no byproduct emissions, no noise, is lightweight, compact and intelligent,” Cornes says.