Fort Wayne, Indiana, USA: Tippmann Engineering’s QuickFreeze+ In-Rack Freezing System has been installed at Canadian pork producer DuBreton’s site.

QuickFreeze+ is modular and allows operators to install and remove units in 10 minutes per pallet position, says Bob Tippmann. “Each QFM unit includes a control board, which connects to the cloud wirelessly through existing facility wi-fi. This allows the user to remotely monitor and control each unit, while important KPI data is pushed to the cloud. Blast freeze requirements for protein export have been changing in the last 3 years, and QF+ allows operators to meet the new requirements quickly.”

Canadian pork producer DuBreton is installing the system in order to meet Chinese export guidelines, requiring all pork products to be frozen at 5°F within a 48-hour time frame from the start of the freezing process. Their current blast freezing methods achieved freeze times in 72 hours.

Chinese export guidelines require all pork products to be frozen at 5°F within a 48 hour time frame from the start of the freezing process. DuBreton’s current blast freezing methods achieved freeze times in 72 hours. Tippmann conducted a test at the DuBreton site with data loggers that measured time and temperature with results of 5°F in 35.83 hours and -4°F in 48 hours.

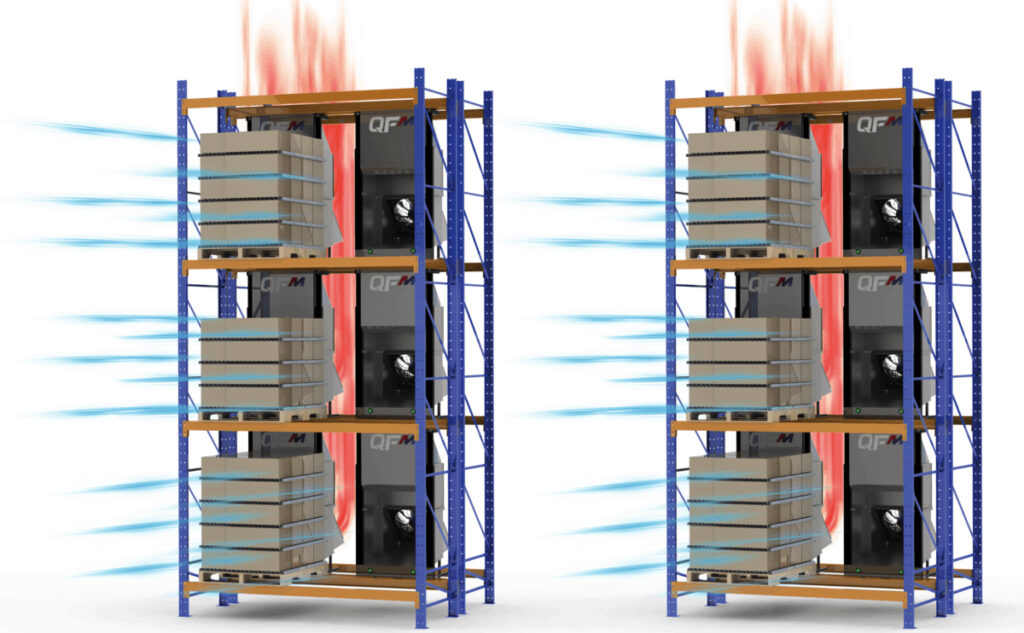

As a result of these findings, duBreton ordered 216 pallet positions of QF+ In-Rack Freezing system. It replaces traditional blast freezing methods by pulling air through the product delivering predictable and consistent freezing instead of blasting air around the pallet, Tippmann says. Additionally, QF+ can also reduce energy costs by up to as much as 50%, he says.

The July issue of Cold Chain News includes a feature with comments from the UK’s major blast freezing operators and equipment suppliers.